An innovative company

Since the beguining in 2003, JM Polymers has been committed to developing sustainable products. The objective is to reduce the carbon footprint by using less polymers in final products from the plastics industry through the use of mineral raw materials. Our granules (masterbatch) make it possible to increase the production capacity of our customers while improving the mechanical properties of the final products. With 20 years of experience, JM Polymers is now one of the European leaders in the manufacture of mineral additive masterbatches for the plastics industry.

Expertise & service

A pioneer for 20 years in the field of highly charged compounds, we can provide tailor-made solutions to our customers.

Quality & environnement

Our products contribute to making the plastics industry more respectful of the environment.

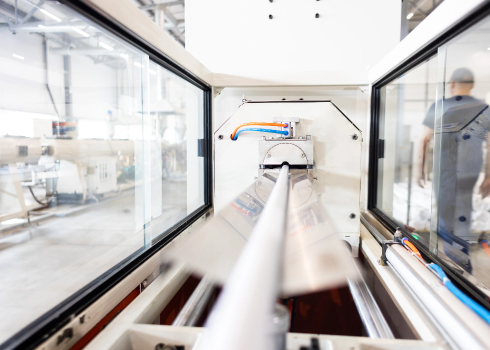

Equipements & partnership

Our machineries made up of different technologies offer a great flexibility for our customers.

A company at your service

Expertise

At the heart of innovation, we have built our own machines at the begining to manufacture new generation plastic materials based on functional mineral fillers. Our Cacolin® and Talcolin® ranges combine economic gain and technical advantages for a real environmental impact. Our range also contains additive masterbatches to facilitate manufacturing processes and improve the performance of our customers’ finished products.

Thanks to a permanent investment in our manufacturing processes, we support our customers in their developments and expand our knowledge to new applications. We adapt to all the specifications according to our customer needs in order to provide a personalized solution.

Our Research Development and Quality Control laboratory is equipped with the latest generation equipment: Melt Flow Index, calorimetric differential spectrometer, infrared spectrometer, humidity meter, oven, double weighing scale, filter test… We carry out tests on granules, but also on final products, especially films. We have the following documents available to our customers: technical data sheets, safety data sheets, food certificates, REACH information. Internal audits are possible at any time. We are ISO 9001 certified.

JM POLYMERS continues today to focus its efforts on the path of energy reduction at each level of the production chain. The manufacture of products based on mineral fillers offers the possibility of reducing the use of petroleum derivatives, while reducing energy consumption.

50000 Tons

Annual capacity of masterbatches with mineral fillers.

5000 Tons

Annual capacity in additive masterbatches.

50% turnover for exportation

In more than 20 countries.

Our range of products

A range of products adapted to your needs

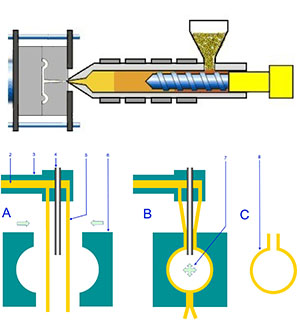

Extrusion of films

LLDPE matrix, CaCO3 or fine Talc filler

Gain in the transformation process: increase in productivity and machine speed, reduction in specific energy consumption, better homogenization, stability of the extrusion bubble…

Gain in the quality of the final product: raw material savings, improved mechanical properties (rigidity, impact resistance, tear resistance, etc.), anti-block action, reduction in sealing temperature for bag welds, improved barrier properties…

Applications: FFS bags, technical films (construction, office materials etc.), checkout bags, garbage bags, agricultural films, food packaging, HD films, door and window profiles, pipes, etc.

Injection

LLDPE and PP matrix, CaCO3 or Talc filler

Gain in the transformation process: increase in productivity, reduction in specific energy consumption, reduction in cycle time by faster cooling, reduction in shrinkage, etc.

Gain in final product quality: raw material savings, improved rigidity, better dimensional stability, better impact resistance, improved HDT (Heat Distortion Temperature under load)

Applications: Garden furniture, car parts, pipes etc.

Thermoforming and cast extrusion

PS or PP matrix, CaCO3 or Talc matrix

Gain in the transformation process: increase in productivity, reduction in specific energy consumption, reduction in cycle time, reduction in the shrinkage of thermoformed parts, etc.

Gain in quality of the final product: raw material savings, improved rigidity, better dimensional stability, reduction in welding temperature, easier printing

Applications: sheets and plates for food packaging, disposable tableware, trays, yoghurt pots, cups, flower pots, displays…

Our certifications

Prevent plastic granules losses

After an external BCS audit (approved body) and thanks to the work of all our teams, JM POLYMERS can now guarantee its compliance with the decree of 16.04.2021 relating to the prevention of plastic granule losses.

ISO certification

After an external BCS audit (accredited body) and thanks to the work of all our teams, JM POLYMERS renewed its ISO 9001 version 2015 certification in 2022. Our quality management system strives for constant customer satisfaction.

A plant with several technologies

They trust us

A question ? Please contact us

For any questions and requests for information, use the form, specifying the subject of your message. We will respond as soon as possible !